ELECTROSPINNING & ELECTROSPRAYING

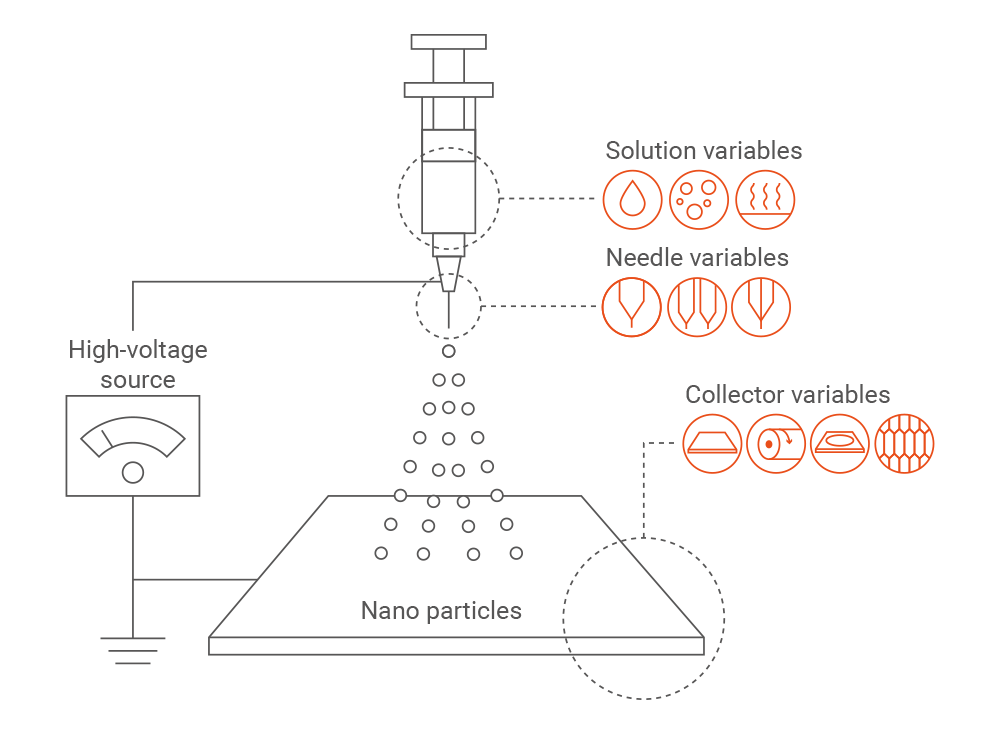

In the traditional electrospraying system, a polymeric solution is loaded into a syringe connected to a metal needle (spinneret). A high voltage (10-30 kV) is then applied to the solution, and a grounded or oppositely charged target (collector) is placed some distance from the polymer solution in order to collect the produced particles. In particular, the polymer solution is held by its surface tension at the tip of the spinneret; when the electric field is applied, charges are induced and accumulated on solution surface, where mutual charge repulsion causes a force opposite to the surface tension.

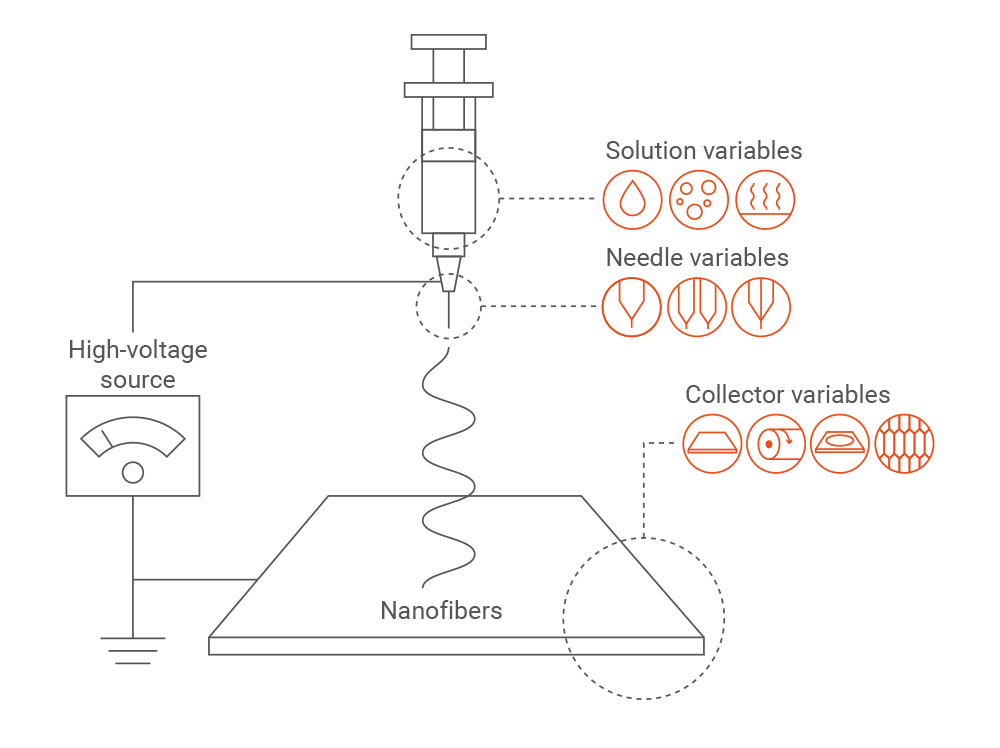

As the electric force increases, the surface of the solution drop elongates to form a conical shape (Taylor cone), and a charged jet of the solution is then formed. This jet travels through the instability region, where bending and whipping movements, together with solvent evaporation, cause jet thinning. Finally, micro- or nano-particles are deposited on the collector.

Electrospinning is a fabrication technique for uniform micro- to nano-fibers which shares the same physical principles than electrospraying. Both processes can be carried out with SKE Research Equipment E-Fiber setups, and the only difference is related to the solution composition used. In fact, solutions with low polymer concentration and low viscosity will more likely generate particles, while solutions with higher polymer concentration and viscosity will produce fibers. The standard set-up is also referred as “needle electrospinning”.

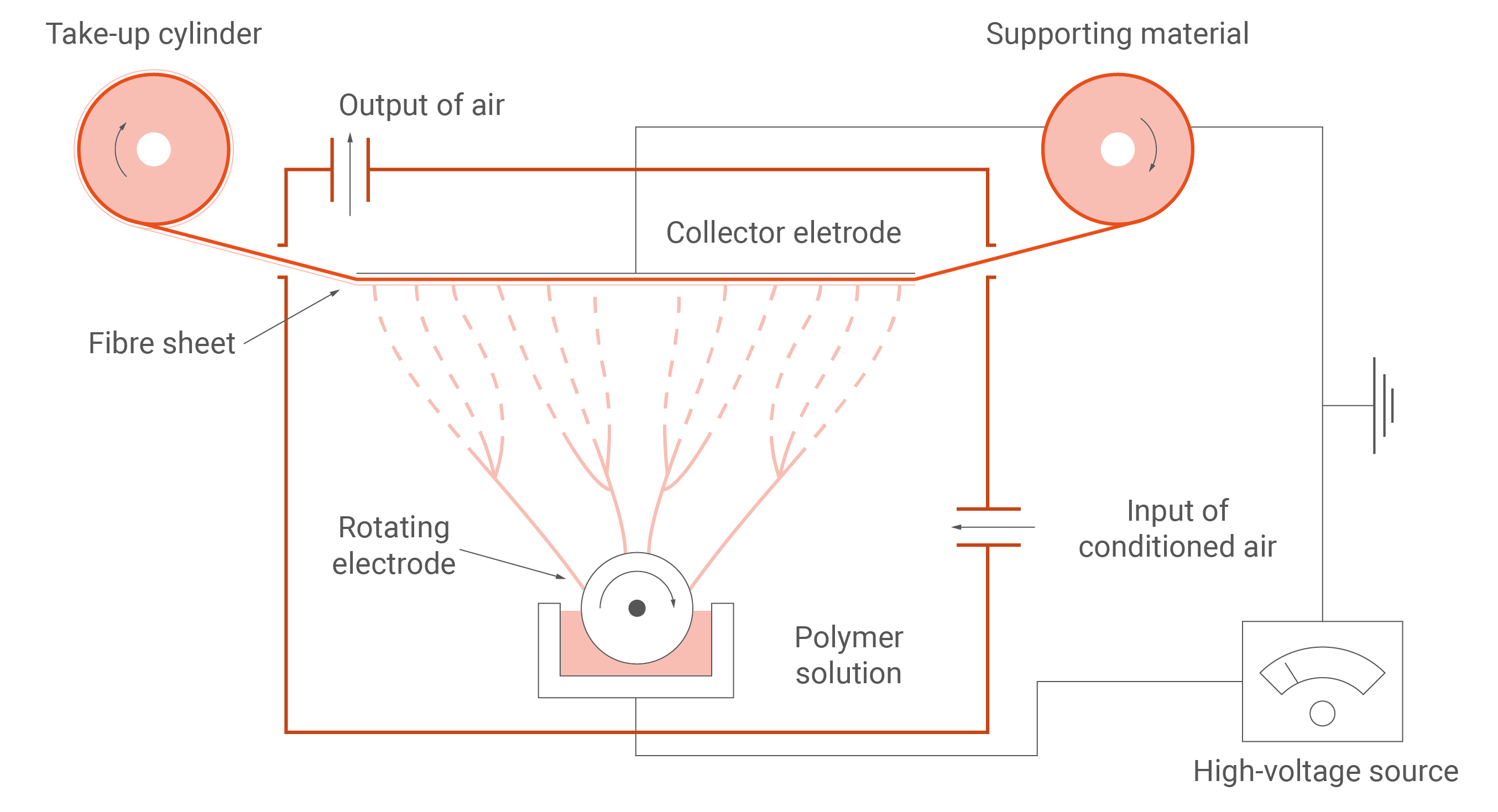

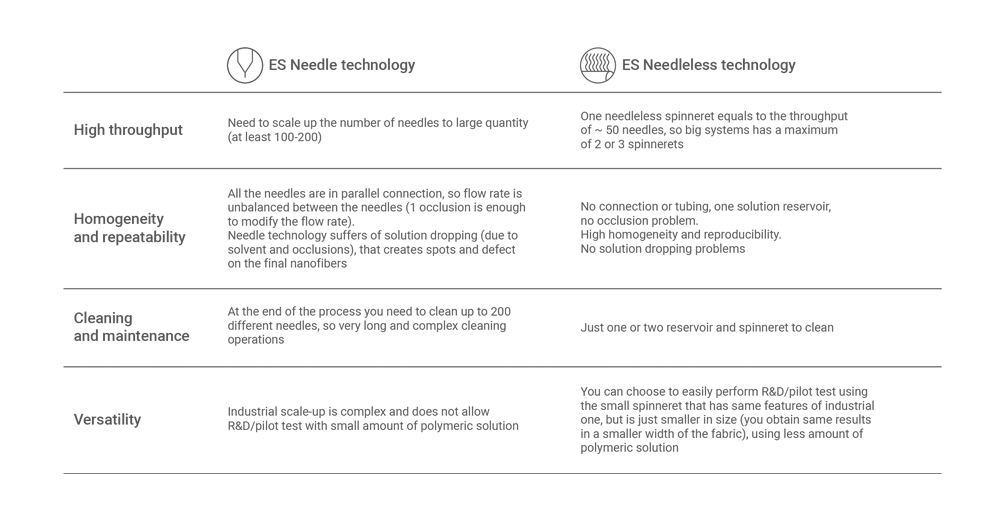

ELECTROSPINNING - NEEDLE vs NEEDLELESS TECHNOLOGY

The main disadvantage of traditional electrospinning setup is its low productivity, related to the limited size of needle. In order to overcome this limitation, SKE Research Equipment has designed and developed an innovative Needleless Electrospinning technology, that allow to scale-up the fabrication efficiency up to 100 times, while keeping the process simple and easy to control. Therefore, we at SKE can exploit the benefit of both technologies, using the versatility of needle systems in lab and research applications, and the high-throughput of the needleless systems for pilot and industrial scale of manufacturing.